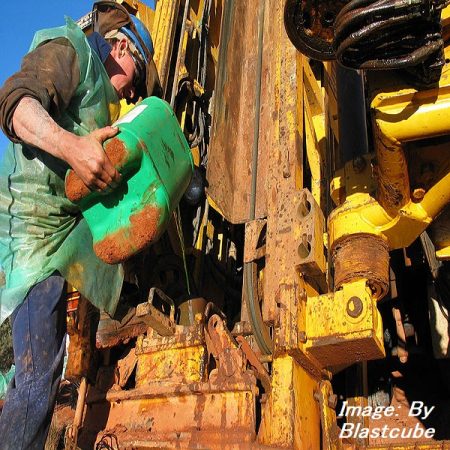

The NTT automatic coresaw is a patented industrial machine for use in the mining sector. Particularly on mineral exploration projects, during the core drilling phases. Allowing users to efficiently, safely, and accurately cut geological core samples down their lengths. It features a system that is fully automatic which you can monitor from beginning to end. This drastically increases productivity and efficiency and is a sure beneficial addition to your project’s requirements.

Automatic Management System

An integrated system allows for the automatic operation of the NTT core saw. Allows a single user to operate it, thanks to the yellow preload rollers, which eliminates the need to lift samples onto the cutting belt. Once loaded onto the dual conveyor belt, your core sample will steadily move along, making contact with the saw blade, and will be cut.

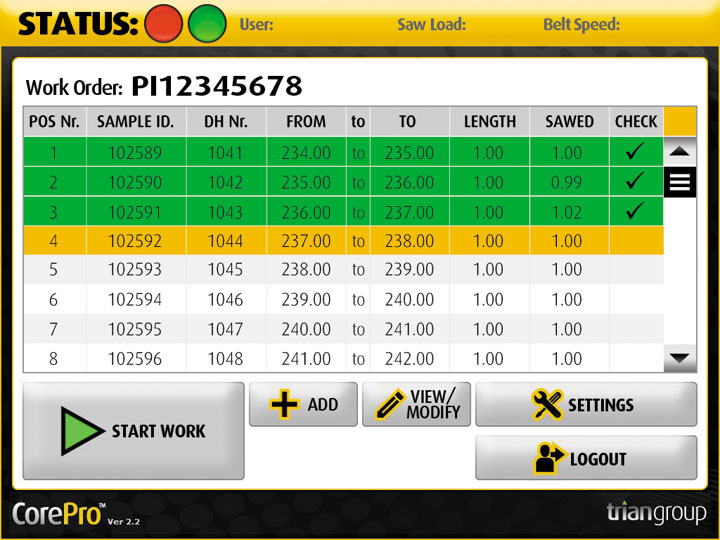

Workflow Optimisation and COREPRO™ Automation Software

The NTT automatic coresaw is designed to optimise drilling and mineral exploration site workflow procedures. Featuring a system that saves all of your cutting data. Processes data recording (actual metres, effective working time), assigns RFID – tags, has a user login system and saves each user’s work and logging data. Furthermore, owing to the various hardness users will encounter on various projects. The saw will adjust its cutting speed automatically upon sensing the various hardness of the material it is cutting. The data of which can be beneficial, for project management and reporting. Users accomplish this with the COREPRO software that comes with the machine, a simple and intuitive system that you can navigate via the built-in touchscreen.

Safety and Maintenance

Built to a high standard with quality components, the coresaw is completely safe when used correctly. Featuring yellow safety guards which automatically cut off the power when the guard sensors are activated. A protective case covers the blade, which cuts out if you open it, further reducing the risk of injury. In addition, the machine features connections for fitting dust extraction devices to it, which in turn reduces dust particle emissions which often contain harmful mineral substances. This is further to the recirculating water system providing users with the option to use either. Water can be fed to the machine via a standard half-inch connector. The system will also automatically shut off the water feed when the saw is not running. Further leading to water use reduction, project savings, and reducing its environmental impact. The dust and water meet protection – Class IP64. The NTT coresaw is also fully certified for European and North American markets, meeting their respective safety standards. (CE, ETL).

Machine Specifications

As expected, the NTT Automatic Coresaw is built from high-quality, precision components and boasts impressive technical specifications. These include a 7.5 kW motor which makes light work of even hard aggregate materials, such as silicates, granites, basalt, dolerites, and more. The system can cut up to 2 meters of material per minute under optimal conditions with automation and cut core diameter sizes from 30 to 85 mm for both the M1 and M2 models, whereas the M3 model can cut between 30 mm to 127 mm.

Cutting Blades

The above is in part thanks to its 350 mm diameter blade which uses a 60 mm diameter bore. This is advantageous over other core saws, as many will allow the use of general construction blades. Which may cut rock, but are not specifically for this purpose or over long periods of time. The NTT core saw and its specific blades are for cutting through geological rock only with a long life in mind. Furthermore, NTT blades have a thicker bore where users secure the disc to the machine. This provides far better stability to the disc when cutting while also working to reduce noise levels. The cutting covers all four main core diameters for mineral exploration on the M1 and M2 models. Whereas the M3 can handle larger diameter samples, up to 127 mm, where cores are often found in geotechnical engineering, construction, oil, gas, and ice coring.

With its ergonomic design, the machine is also easy to clean and maintain, with everything simplified, for quick and fast-changing of spare parts, even when on-site. Overall, this excellent core saw is an ergonomic design that maximizes the throughput of core samples.